Fatigue Cycler

An excellent new tool for fatigue cycling of dental materials and structures is here!

|

To simulate the fatigue of biomaterials such as dental composites, the Fatigue Cycler uses powerful solenoids to provide smooth, cyclic loading to levels of up to 375N. Up to four specimens at a time can by cycled while suspended in recirculating, heated water. The force levels are displayed and controlled on a personal computer.

No more tying up your single-axis test machine for weeks! With the Fatigue Cycler, the loading routine can be varied to apply a sinewave, triangular or step wave at frequencies up to 3Hz and cycle from 20N to 375N. Closed-loop control is provided by low profile, in-line load cells to continuously calibrate the individual coils. The PID control software comes installed on a new notebook computer. This flexible and intuitive control package allows the user to configure unique test conditions and display arrangements using a drag-and-drop interface or use the standard control packages provided. It also has the capability to monitor eight additional analog signals and eight digital signals and stream readings to data logs. The Fatigue Tester is individually crated and shipped to your location. It can be easily assembled and operated by laboratory personnel using the included instruction manual. Or an on-site installation and training visit can be arranged. The instrument and all of its components are covered by a six month parts and labor warranty. The machine consists of the computer, the power supply/control console, a powerful quad-core notebook computer, and the test frame with four test stations. |

|

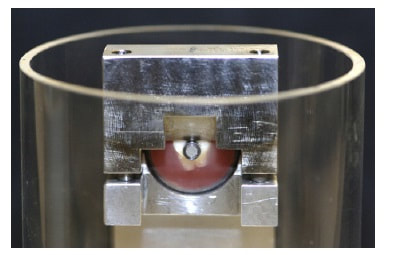

TEST FIXTURES: A variety of test fixtures are available for this flexible new platform. The system comes with adjustable-length stainless steel indenters as standard equipment. Specimen holders include:

|

|

SENSORS: A variety of sensors can be configured to monitor the condition of the specimens including:

|

Spotlight on Research

|

Seattle-based Kois Center has published numerous studies using their Fatigue Cycler by Proto-tech, such as: Chaiyabutr Y, Kois JC. Comparison of load-fatigue performance of a CAD/CAM tooth-color crown. Kois Center Research 2015.

Ground-breaking research on the shear bond strength of enamel bonds in fatigue was reported by R.L. Erickson et al in Dental Materials in 2008 using the Proto-tech Fatigue Cycler using custom-developed shear testing fixtures. In a review in 2022, referring to the system that Erickson used, Tsujimoto et al stated in Dental Materials that the "Fatigue Cycler was a good machine from a mechanical perspective."

|