Oral Wear Simulator

|

|

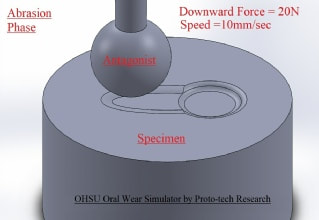

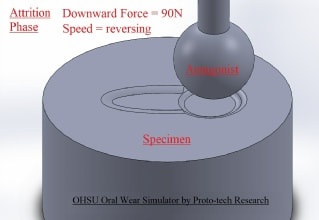

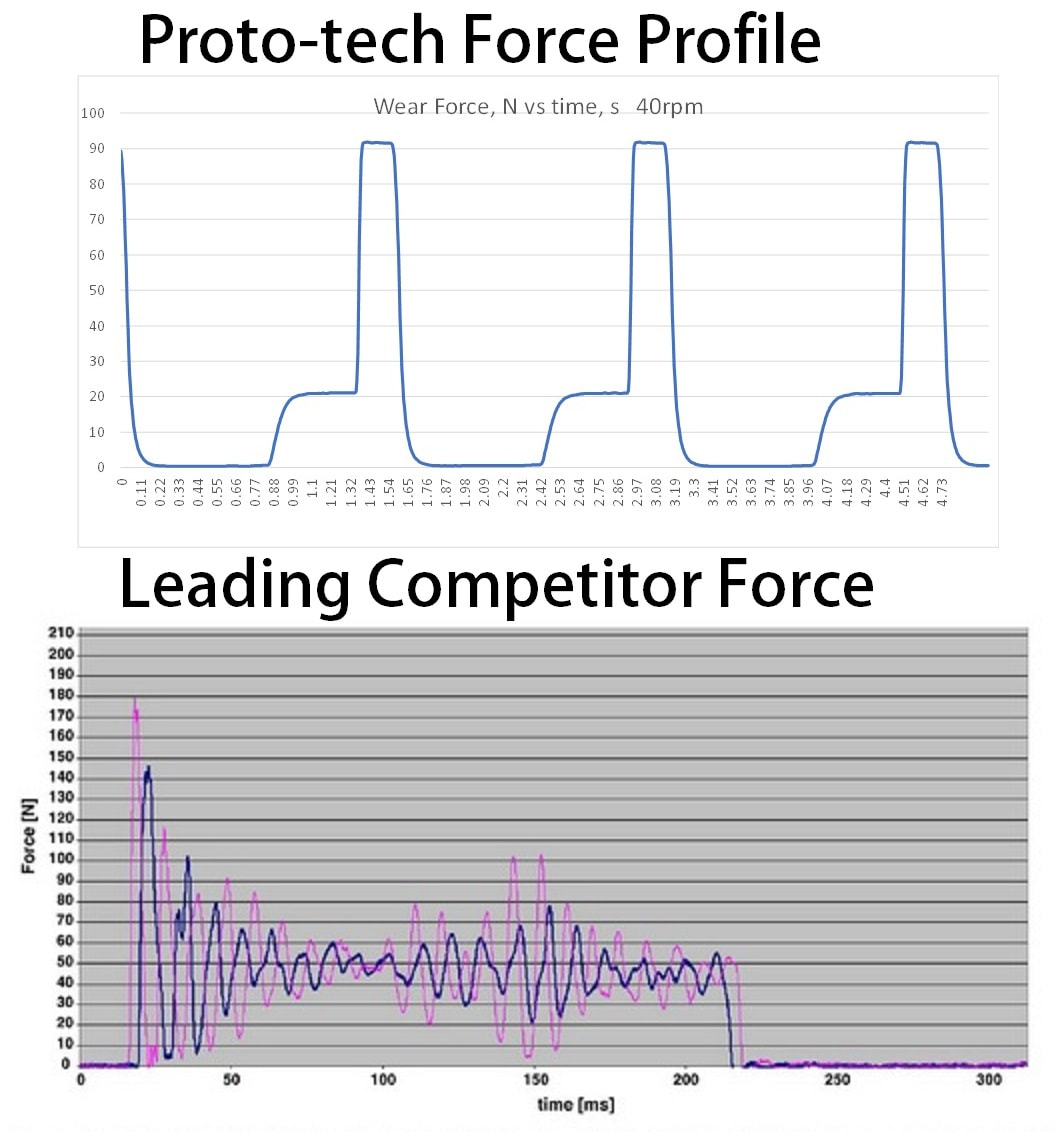

This is the leading oral wear simulator which research has found to produce and simulate realistic measurements of the two major wear mechanisms, abrasion and attrition on each specimen. A ball-on-plane arrangement transmits a low force during sliding of 20N, followed by a 90N pulse at the end of the pass to produce a revolutionary slide-and-clench action. The two-phase wear pattern is then measured. Developed at OHSU, results from numerous round robin studies have found a strong correlation to occlusal-contact and contact-free measurements from in vivo studies. The system has been used by numerous institutes and manufacturers to characterize wear of composites, adhesives, ceramics, amalgams, and natural dentition.

Specifications:

Wear Regimen:

Hardware:

Start-up kit: All necessary hand tools including 6 mm allen wrench, 4 mm and 8 mm open-end wrench. A supply of 100 ceramic balls and nylon screws, and 50 acrylic specimen rings. Instruction Manual. Requirements:

|